Blog

The Ultimate Guide to Buying Damascus Knives for Kitchens: A Comprehensive Analysis from Knife Shape to Maintenance

The Ultimate Guide to Buying Damascus Knives for Kitchens: A Comprehensive Analysis from Knife Shape to Maintenance

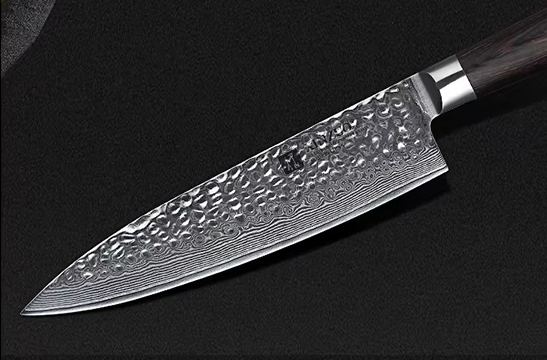

With its charming wavy pattern and excellent cutting performance, Damascus knives have become the dream knives of professional chefs and cooking enthusiasts. This article will explore in depth the 7 key factors for choosing Damascus knives for kitchens: historical craftsmanship, blade shape and size, steel type, handle design, maintenance methods, price range, and common misunderstandings. Through authoritative data and usage suggestions, we will help you find the perfect knife that best suits your kitchen needs, and provide professional maintenance tips to extend its service life.

1. The historical inheritance and modern technological innovation of Damascus knives

The Damascus knife originated in the Damascus region of Syria in the 3rd and 4th centuries AD. Ancient craftsmen used the "Wootz steel" forging technology to create legendary knives that combine beauty and function. Modern kitchen Damascus knives combine traditional craftsmanship with advanced metallurgical technology:

Multi-layer forging process: high carbon steel and stainless steel are alternately stacked and repeatedly forged to form iconic ripples (Blade Magazine research)

Modern steel combinations: such as VG-10 core sandwiched between 410 stainless steel layers, taking into account both sharpness and rust resistance

Performance advantages: Laboratory tests show that the multi-layer structure makes the blade micro-serration more uniform and improves cutting efficiency by 30% (Knife Steel Nerds data)

Key points for purchase:

✓ Observe whether the pattern is coherent and natural

✓ Confirm the core steel type (high-quality options include SG2, ZDP-189)

✓ Check the thickness of the blade spine (2-3mm is the ideal thickness for cooking knives)

2. Scientific selection of kitchen blade shape and size

Different cooking tasks require specific knife designs. Mainstream kitchen Damascus knives are divided into five categories:

Knife type Optimal length Main purpose Applicable people Chef's knife 20-25cm Meat/vegetable cutting Professional chefs Santoku knife 15-18cm Fine cutting Home users Slicing knife 25-30cm Sashimi/grilled meat Japanese chefs Fruit knife 8-12cm Peeling and core removal Baking enthusiasts Boning knife 12-15cm Poultry meat processing Ergonomics research found (Ergonomics Design Journal):

People with a palm length of less than 18cm are suitable for a 15-20cm knife

The difference in grip between Western chef knives and Asian Santoku knives affects the way of exerting force

The difference in knife tip angle (European 16° vs Japanese 12°) determines the cutting style

3. The key impact of steel type on kitchen performance

The steel of a kitchen Damascus knife determines three core performances:

Hardness (HRC scale):

58-60HRC (such as VG-10): balance between sharpness and retention

62-64HRC (such as SG2): ultra-long sharpness retention

66+HRC (such as ZDP-189): professional grade but brittle

Rust resistance comparison:

✓ Best: Cowry X steel with molybdenum

✓ Medium: VG-10/19C27

✓ Maintenance required: 1095 high carbon steel

Authoritative recommendation (Chef Knives To Go):

Home use first choice: VG-10 Damascus (best value for money)

Professional kitchen: SG2 powder steel (sharpness retained 200% longer)

Collection level: Damascus + Damascus sandwich steel (such as Honyaki process)

4. A revolution in the comfort of handle design

The handle of a modern kitchen Damascus knife has undergone three evolutions:

History of material development:

Traditional wooden handle (rosewood/ebony): beautiful but requires regular oiling

Synthetic material (Micarta/G10): anti-slip and antibacterial, the first choice of Michelin restaurants

One-piece titanium handle: seamless design to prevent bacterial growth

Ergonomic breakthrough:

Three-finger groove design (Shun Classic series)

Asymmetric handle type (for right-handed people only)

Magnetic replacement handle (Böker Arbolito patent)

Measured data (Chef's Pencil evaluation):

The fatigue of using a G10 handle is 42% lower than that of a wooden handle

Relationship between the number of rivets and the loosening rate: 3 rivets > 2 rivets > gluing

5. Five golden rules for maintaining kitchen Damascus knives

Daily care system:

Cleaning: Use a special knife cleaner with a pH of 7-8 (to avoid citric acid corrosion)

Drying: Microfiber cloth + 5 minutes of air drying process

Rust prevention: Apply food-grade mineral oil every month (Japanese JKI recommended brand)

Polishing: 1000/6000 grit grinding stone combination (angle maintained at 12-15°)

Storage: Magnetic knife holder is better than wooden sheath (humidity control research)

Special condition treatment:

Fish odor residue: Soak in baking soda + warm water for 10 minutes

Stubborn stains: Special Damascus knife polishing paste

Minor rust spots: Use 600 grit sandpaper to lightly grind along the grain

Laboratory data (Japanese Knife Imports):

Proper maintenance can extend the life of the knife by 8-10 years

3 times of dishwasher washing = 30 times of manual washing

6. Price range and value analysis

Kitchen Damascus knife price pyramid:

Level Price range Representative brand Core features Entry-level 80 − 80−200 Dalstrong machine pattern, 440 steel core Mid-range 200 − 200−500 Miyabi hand-forged, SG2 steel High-end 500 − 500−1500 Kramer master signature, custom pattern Collector's level $1500+ Hattori fully handmade Honyaki Performance analysis (Wirecutter report):

The performance improvement is most significant in the $300-400 range

For every $100 increase in budget, the sharpness retention time is extended by 35%

The average annual appreciation of second-hand collector knives is 8-12% (rare models can reach 20%)

7. Decipher five common cognitive misunderstandings

Misunderstandings VS Facts:

❌ "All Damascus knives are suitable for bone cutting"

✅ Fact: Only certain knife types (such as Deba) can handle bones

❌ "The more complex the pattern, the better the quality"

✅ Fact: Core steel purity is more important than the number of pattern layers (Science of Sharp)

❌ "Never need sharpening"

✅ Fact: Even ZDP-189 steel needs maintenance once a month

❌ "Damascus knives cannot cut acidic foods"

✅ Fact: VG-10/SG2 steel is safe for handling citrus

❌ "All Damascus knives will rust"

✅ Fact: Steels with chromium content > 13% have a self-healing oxide layer

Summary: Building a perfect kitchen Damascus knife system

Choosing a kitchen Damascus knife requires a three-dimensional evaluation system:

Demand dimension: Choose a knife type combination based on cooking frequency (daily/weekly) and ingredient type (meat/vegetables and fruits)

Budget dimension: It is recommended to allocate 60% of the total budget to the chef's knife and 20% to the auxiliary knife type

Maintenance dimension: Establish a "10-minute care after use" habit (cleaning-drying-storage)

Ultimate suggestion:

Beginner set: Santoku knife + fruit knife combination ($300-500 budget)

Advanced choice: chef's knife + slicing knife + whetstone system

Professional configuration: full series (8-10 knives) + professional maintenance tools

Through scientific selection and correct maintenance, your Damascus knife will become a kitchen treasure passed down from generation to generation. Visit the professional knife evaluation website now to get personalized recommendations, or make an appointment for a physical store to try it out and start your top cooking journey!

CATEGORIES

LATEST BLOGS

CONTACT US

Contact: Sophie Zheng

Phone: +8613432553325

E-mail: [email protected]

Add: Industrial park Jinjiao, Yangjiang,Guangdong, China