Blog

Featured Guide: How to Choose a Butcher Knife Set with Real Durability and Excellent Performance

Featured Guide: How to Choose a Butcher Knife Set with Real Durability and Excellent Performance

In the kitchen, a set of high-quality butcher knife set can not only improve the quality of food processing, but also significantly improve the operation efficiency and safety. Starting from 8 key points, this paper deeply discusses the key components of the butcher's knife set, the chef's core cutter role, durability and performance indicators, blade materials and structural technology, safety design elements, and maintenance and performance optimization strategies. By combining with authoritative data and empirical research in the industry, it helps family chefs and professionals to choose the most suitable kitchen knife set/kitchen knives to ensure long-term return on investment.

The following are eight arguments in this article, each with an argument, which is expanded layer by layer.

1. The key component of the butcher knife set is to diversify the types of knives to cover all kitchen needs.

Argument:

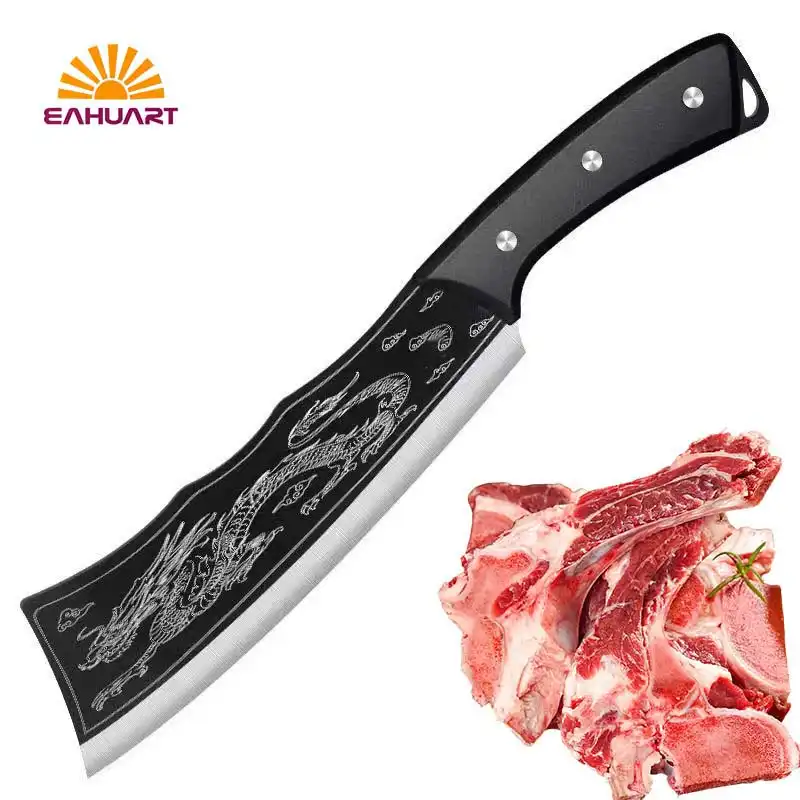

1) A complete butcher knife set usually includes Chef's Knife, Boning Knife, Cleaver, Carving Knife, Utility Knife, etc. Each kind of knife plays a different role in the food processing task, for example, a machete is used to process bones, and a carving knife is used to cut thin slices to show the effect.

2) In Food & Wine's "The Guide to Kitchen Knives", it is pointed out that the correct combination of knives can make the daily tasks of the kitchen such as cutting, chopping, peeling and slicing all at ease, thus saving time and energy and reducing the waste of ingredients or operational errors caused by improper knife types.

3) If there is a lack of a key tool, such as a deboning knife, it will lead to inaccurate cutting and more waste of marginal meat when dealing with bone-bearing food such as fish, chicken or pig.

2, Chef's Knife is the center of the Kitchen Knife Set, which makes the greatest contribution to performance and efficiency.

Argument:

1)Chef's knife is generally about 8 inches long, and its blade geometry design makes it have multiple purposes such as cutting, slicing, chopping and so on. An excellent chef's knife can replace several special knives, but on the contrary, it is difficult to cope with all tasks.

2)In the evaluation of Serious Eats, the chef's knife is often rated the highest because of its balance, sharpness and coordination of knife weight. Serious Eats

Poor design of chef's knife (such as off-center of gravity of handle and unbalanced blade) will lead to wrist strain and low efficiency when cutting meat or vegetables.

3, durability and performance indicators (such as hardness, edge retention) are important factors to distinguish high-end butcher knife suits.

Argument:

1)The Rockwell Hardness, HRC) of the tool is the key index to measure its sharp edge in use. Usually, the hardness of the blade in a high-quality butcher knife set is 56–61 HRC. While maintaining sharpness, it is also necessary to avoid brittle fracture. These values mentioned in the original text of this paper are widely recognized in practice.

2)Take steel grades such as VG-1 and VG-10 as examples. These are well-known high-carbon stainless steel. When they are used in kitchen knives, their carbon content is matched with alloy elements such as Cr/Mo/V, which makes them have strong corrosion resistance and good edge retention.

3)In the analysis of "Knife Steels Rated by a Metallurgist", the steel with more carbon and vanadium has better edge retention, but its toughness may decrease, so it is necessary to strike a balance between hardness and toughness.

4, blade material science and structural technology (forging vs stamping, full keel vs semi-keel) determine the mechanical properties and use experience.

Argument:

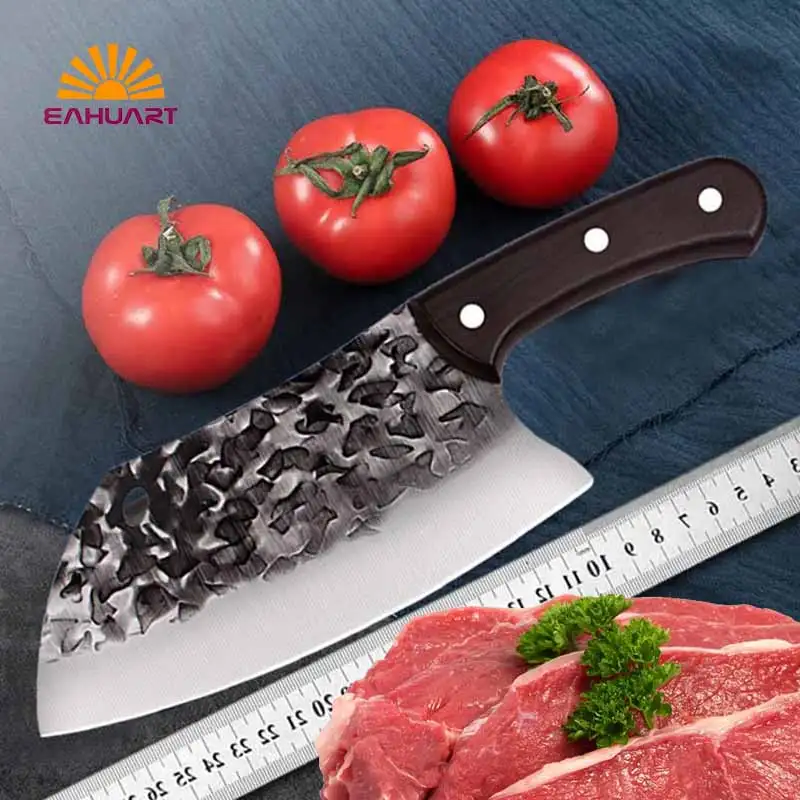

1)Forged tool is made of a whole piece of steel by hammering and heat treatment, with a denser internal metal structure and strong tensile and impact resistance; In contrast, Stamped tools are light in weight and low in manufacturing cost, but they are usually not as good as forged products in hardness and durability.

2)The Full Tang structure makes the blade metal run through the whole length of the handle, with more uniform weight distribution and higher strength at the joint, which is not easy to break or loosen. Although the semi-keel or part of the keel structure is light, there may be problems such as the separation of the handle from the body and the loosening of the handle when cutting or chopping bones under heavy load.

3)The steel grade of different materials and heat treatment process (quenching, tempering, cold working, annealing, etc.) have a decisive influence on the hardness, elasticity and durability of the tool. For example, VG-10 steel can achieve excellent microstructure fineness and edge sharpness after specific quenching and grinding.

5, safety design is not only about avoiding accidents, but also directly affects operational efficiency and user confidence.

Argument:

1)Bolster and thickened spine form structural support and finger protection at the joint between the blade body and the handle, so as to reduce the hand injury caused by knife sliding or uneven strength.

2)Anti-skid materials (such as Santoprene™, Micarta, G10, stabilized wood, etc.) can keep a good grip in wet or greasy environment, reduce the risk of slipping and reduce operational fatigue.

3)The good design of weight and balance improves the controllability of the tool in use. When the weight is not properly concentrated at the end of the knife handle or blade, the user needs extra force to control it during the cutting process, thus reducing efficiency and being prone to fatigue.

6. Maintenance and performance optimization are the key links to prolong the service life of Butcher Knife Set.

Argument:

1)sharpening and honing regularly can restore or maintain the geometric shape of the blade and prevent the edge line from becoming dull. Although the blade with high hardness is sharp, it is easier to break, and it will damage the blade if it is not repaired in time.

2)For carbon steel tools, after cleaning, they must be thoroughly dried and coated with antirust oil to avoid corrosion. Although the high-carbon stainless steel tool has good rust resistance, it may produce spots or oxidation if it is stored in wet or in contact with acidic food, which will affect its appearance and performance. This is illustrated in the comparison of materials from Opinel.

3)The storage method is also very important. The cutting tool should be stored separately in the tool holder, tool sleeve or slot to avoid the impact or deformation of the cutting edge caused by the contact of the cutting edge with hard objects. Using wooden or plastic chopping boards can protect the cutting edge better than glass or stone chopping boards.

7, durability and performance optimization need to pay attention to edge retention and chemical composition of materials.

Argument:

1)As mentioned above, steel with high carbon content can keep the edge better. Research such as "Knife Steels Rated by a Metallurgist" shows that vanadium and other elements (such as molybdenum molybdenum and cobalt cobalt) can improve wear resistance and oxidation resistance.

2)Martensitic stainless steels such as VG-10 and 440C can achieve a good compromise between edge preservation and corrosion resistance due to their alloying elements and heat treatment. 440C steel can reach about 58-60 HRC after proper quenching and tempering, and has good wear resistance. Wikipedia

3)In the comparison of Kitchen Steel vs Stainless Steel, although high carbon steel has high sharpness, it is sensitive to corrosion; The modern high-carbon stainless steel tries to combine the advantages of the two, so that the tool can be maintained easily and kept sharp for a long time.

8, find the best balance between efficiency and input cost.

Argument:

1)The price of high-end materials and excellent technologies (such as VG series steel, forging and full keel structure) is usually higher, but the long-term life, low maintenance frequency and cost savings brought by the improvement of operation efficiency can be significantly rewarded in professional kitchens or frequent use scenarios.

2)For home cooks or people who use it less frequently, a mid-range kitchen knife set with reasonable structure and proper maintenance can almost approach the more expensive model in terms of performance and service life, with high cost performance.

3)Users can invest in stages: first buy key core knives (such as chef's knife, deboning knife and multi-purpose knife), and then add special knives such as carving knife and machete with the increase of cooking demand and budget. This not only reduces the initial cost, but also improves the use efficiency.

A table combining the above arguments: comparison of performance indicators

The following table compares the performance of different materials/structures in key performance, which helps to clearly understand how to make choices in durability, edge preservation, safety and so on.

| Performance Indicator | High-Carbon Stainless Steel | Traditional Carbon Steel | VG-Series Steel (e.g., VG-10) | Stamped Tool Structure | Forged Full Tang Structure |

|---|---|---|---|---|---|

| Edge Retention | High | Very High | Very High | Low | High |

| Corrosion Resistance | Excellent | Poor | Excellent | Depends on Material | Excellent (if material matches) |

| Hardness (HRC) | Usually 58-61 | Usually 60-64 | Medium-High | Low-Medium | High and more stable |

| Toughness / Not Brittle | Good | Low | Medium-High | Low | Very High |

| Weight / Handling | Medium-Light | Heavy | Depends on Knife Type | Lightest | Heavier but well-balanced |

| Safety Design | Good (finger guard, non-slip handle, etc.) | Sometimes lacks anti-slip or finger guard | Well-designed | Usually simple | Supports overall structural strength & finger protection |

| Maintenance Difficulty | Medium (requires regular cleaning) | High (prone to rust, frequent care needed) | Medium-High | Low-Medium | Medium, but durable once built |

| Cost | Medium-High | Medium-Medium-High | Relatively High | Low | High |

9. External authoritative research and industry standards support the above performance and purchase suggestions (enhance credibility).

Argument:

1) In the article "Knife Steels Rated by a Metallurgist", the specific differences of wear resistance, toughness and corrosion resistance of different steel grades (carbon steel, stainless steel, high-carbon, vanadium-containing steel grades, etc.) are analyzed from the metallurgical point of view, and it is pointed out that the steel grades containing vanadium and well forged and heat-treated are better in Butcher Knife Set. knifesteelnerds.com

2) Opinel's comparison of "stainless steel vs. carbon steel knives" also provides an authoritative view: although high carbon steel is sharp, it needs extra maintenance, and stainless steel (especially high carbon stainless steel) is more worry-free in rust prevention and daily cleaning.

3) WG- series steel (VG-10, etc.) is listed as an industry-recognized blade material in Wikipedia and professional tool materials, which has both hardness and corrosion resistance, and is often selected by users and manufacturers of kitchen knives.

Extension of safety design details: avoiding injury and improving maneuverability

In terms of safety design, the following details are particularly important:

Bolster: The structure should be smooth and naturally transition with the blade, and there should be no sharp edges to prevent fingers from accidentally slipping in.

Material and shape of the handle: the material should be non-slip and the shape should conform to the natural grip of the palm; Long handle or thick handle should have sufficient support when cutting heavy objects.

Weight and balance: the center of gravity of the tool should usually be at the junction of the handle and the blade, so that it is easy to control when cutting, and it will not be excessively biased forward or backward.

Design of blade tip and back: the blade tip should be firm and not easy to break; The thickness of the spine of the knife is moderate, which has a sense of support and does not affect the flexibility when cutting vegetables.

Maintenance and Performance Optimization Strategy

In order to maintain the performance of butcher knife set, the following optimization suggestions are critical:

1) Regular broaching and sharpening: Use a grindstone (water stone, ceramic stone or grindstone) and a honing steel to keep the cutting edge, broaching the knife before and after each use, and grinding it every 6-12 months for severe users.

Cleaning and drying: wash by hand immediately after use to avoid high temperature and high humidity environment of dishwasher; Dry the tool thoroughly with a dry cloth, especially the carbon steel tool.

2) Rust prevention measures: For carbon steel or incomplete stainless steel tools, it is recommended to use food-grade oil (such as mineral oil or special oil for tools) Bo Tu blade to form a protective layer.

3) Proper storage: use knife rest, knife insert or knife sleeve to avoid the collision of blades; Avoid cutting edge damage caused by scattered knives in drawers.

Proper use: avoid cutting hard objects (such as bones, ice cubes, big shells, etc.) with a knife unless the knife is designed for this purpose; Use a matching chopping block (wood or plastic) instead of glass or marble to maintain the cutting edge.

Summary

Choosing a truly trustworthy Butcher Knife Set/Kitchen Knife Set is not a simple choice of appearance or price, but a comprehensive consideration integrating structural design, material science, durability, safety and maintenance strategy. Through the eight arguments of this paper:

Diversified cutter types to meet all kinds of tasks in the kitchen

Chef's knife is the core of efficiency and performance

Hardness and edge retention are key indicators to test durability.

Forging vs stamping, full keel vs semi-keel affect the performance experience.

Safety design is the basis of protecting operation and user confidence.

Maintenance strategy can prolong service life and maintain performance.

Edge retention and chemical composition of materials are very important to the quality of results.

Find the best balance between cost and efficiency

Combining external research and standard materials (such as VG-10, 440C, etc.), you can confidently choose a butcher knife suit that is durable and excellent in performance, and at the same time conforms to your own usage habits and budget. Correct kitchen skills are not only a tool for cooking, but also a reflection of kitchen efficiency and aesthetics. Take some time to select, maintain and use, and your Butcher Knife Set will accompany you for many years, bringing you a stable, safe and accurate cutting experience.

CATEGORIES

LATEST BLOGS

CONTACT US

Contact: Sophie Zheng

Phone: +8613432553325

E-mail: [email protected]

Add: Industrial park Jinjiao, Yangjiang,Guangdong, China