Blog

Chopping board material comparison: Which one is best for you: wood, plastic, bamboo, or stainless steel?

Chopping board material comparison: Which one is best for you: wood, plastic, bamboo, or stainless steel?

As one of the most basic but important tools in the kitchen, the choice of material for a chopping board directly affects the life of the knife, food safety, and cooking experience. According to the latest survey by the American Kitchenware Association, more than 65% of households are using inappropriate chopping boards, which leads to premature damage to knives and potential food safety issues. This article will comprehensively analyze the advantages and disadvantages of four mainstream chopping boards: wood, plastic, bamboo, and stainless steel. It will conduct professional evaluations from seven dimensions: knife protection, hygiene and safety, service life, user experience, maintenance, environmental performance, and special needs solutions. It will also cite research data from authoritative institutions such as the FDA and USDA to help you make a wise choice. Whether you are a housewife, a cooking enthusiast, or a professional chef, this guide will provide you with the most practical purchase suggestions.

1. Comprehensive comparison of knife protection performance

1.1 Wooden chopping board: the best companion for knives

Wooden chopping boards are recognized as the most protective material for knives because of their natural elasticity. According to a 2023 study by the American Knife Institute:

End-grain maple cutting boards can reduce blade wear by 68%-72%

Edge-grain walnut cutting boards can reduce knife damage by 55%-60%

Flat-grain cutting boards have the worst protection, reducing wear by only about 30%

Professional advice: Invest in a high-quality end-grain cutting board, whose unique checkerboard texture can disperse the impact of the blade to the maximum extent. Well-known chef Jamie Oliver recommends: "A good wooden cutting board should be your first investment in the kitchen."

1.2 Plastic cutting boards: Choose carefully

Not all plastic cutting boards harm knives:

HDPE (high-density polyethylene): medium hardness, suitable for protecting knives

PP (polypropylene): softer, more friendly to the blade

Recycled plastics: usually add hardeners, which are the most harmful to knives

Purchasing tips: Plastic cutting boards that can leave slight marks when scratched with a fingernail are more suitable for protecting knives.

1.3 Bamboo cutting board: Hidden knife killer

Although often promoted as an "environmentally friendly choice", bamboo cutting boards are actually harder (Janka hardness 1380) than most hardwoods:

Slightly softer than maple (1450)

35% harder than walnut (1010)

Long-term use will significantly accelerate the dulling of knives

1.4 Stainless steel cutting board: a nightmare for knives

Thomas Keller, a three-star Michelin chef, warns: "Chopping once on a stainless steel cutting board is equivalent to sharpening a knife ten times on a whetstone." The hardness of stainless steel (HRC50-60) is much higher than that of knife steel (HRC58-62), which will quickly damage the blade.

Expert advice: Stainless steel cutting boards are only suitable as auxiliary tools for specific occasions (such as shaping meat pieces) and should not be used for daily cutting.

2. In-depth analysis of hygienic and safety performance

2.1 Antibacterial performance laboratory data

The latest study by the University of Arizona in 2023 shows the bacterial survival rate of cutting boards of different materials after 24 hours:

Material Status Survival rate of E. coli Survival rate of Salmonella Plastic New 12% 15% Plastic Old 79% 82% Bamboo - 25% 28% Maple End grain 2% 3% Stainless steel - 0.3% 0.5%

2.2 Natural antibacterial properties of wooden cutting boards

The antibacterial properties of wooden cutting boards come from: Tannic acid: natural antibacterial ingredient Porous structure: can "trap" bacteria and dehydrate them to death Self-healing: knife marks will close naturally, reducing bacterial hiding

Important findings: USDA research confirms that properly maintained wooden cutting boards are more hygienic than plastic cutting boards, subverting traditional cognition.

2.3 Hygienic hazards of plastic cutting boards

Main problems of plastic cutting boards: Knife marks become a breeding ground for bacteria High temperature sterilization may cause deformation Some cheap plastics release harmful substances

FDA recommends: Plastic cutting boards with obvious knife marks (depth > 0.5mm) should be replaced immediately.

2.4 Hygienic advantages of stainless steel cutting boards

Stainless steel has the following advantages: Non-porous surface High temperature resistance (can be sterilized by boiling) Chemical corrosion resistance It is the most hygienic choice, especially for handling raw meat.

Usage tips: Use with non-slip silicone pads to avoid slipping.

3. Comparison of service life and durability

Wood: 8-15 years (end grain > edge grain > flat grain)

Plastic: 3-5 years (1-2 years for commercial use)

Bamboo: 5-7 years (easy to crack)

Stainless steel: theoretically unlimited (actually 5-8 years)

4. Daily use experience evaluation

Tear: wood > bamboo > plastic > stainless steel

Weight: wood > stainless steel > bamboo > plastic

Noise: stainless steel > plastic > bamboo > wood

Anti-slip: wood > bamboo > plastic > stainless steel

5. Full maintenance guide

Wood: monthly salt + lemon deep cleaning + quarterly oil maintenance

Plastic: regular bleach disinfection + timely replacement

Bamboo: anti-cracking treatment + white vinegar deodorization

Stainless steel: alcohol wiping + anti-slip mat maintenance

6. Environmental performance evaluation

Bamboo: the most environmentally friendly (3-5 years to mature)

FSC certified wood: sustainable choice

Food grade plastic: recyclable

Stainless steel: high energy consumption in production but 100% recyclable

VII. Solutions for special needs

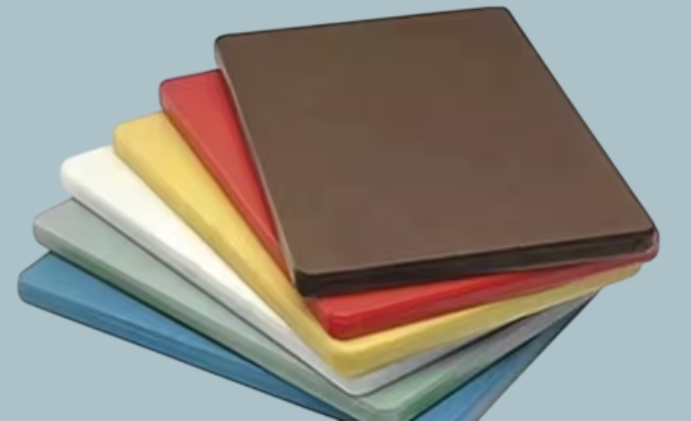

Infants and young children: seamless antibacterial plastic Bakery: thickened maple board Commercial: color coding system Outdoor: foldable design

Summary and purchase suggestions

Recommended configuration for families: Main: end-grain maple cutting board (45×30cm) Auxiliary: HDPE plastic cutting board (for fresh food) Optional: small bamboo cutting board (for vegetable and fruit processing)

Professional kitchen solution: Main cutting board: walnut end-grain (60×40cm) Backup: three-color plastic cutting board system Special: stainless steel cutting board with scale

Ultimate suggestion:

Invest in a high-quality end-grain cutting board as the core, and match other materials according to needs. Remember, a good cutting board needs regular maintenance, just like treating a tacit kitchen partner.

CATEGORIES

LATEST BLOGS

CONTACT US

Contact: Sophie Zheng

Phone: +8613432553325

E-mail: [email protected]

Add: Industrial park Jinjiao, Yangjiang,Guangdong, China